Winning

50 World

championships

Karting program

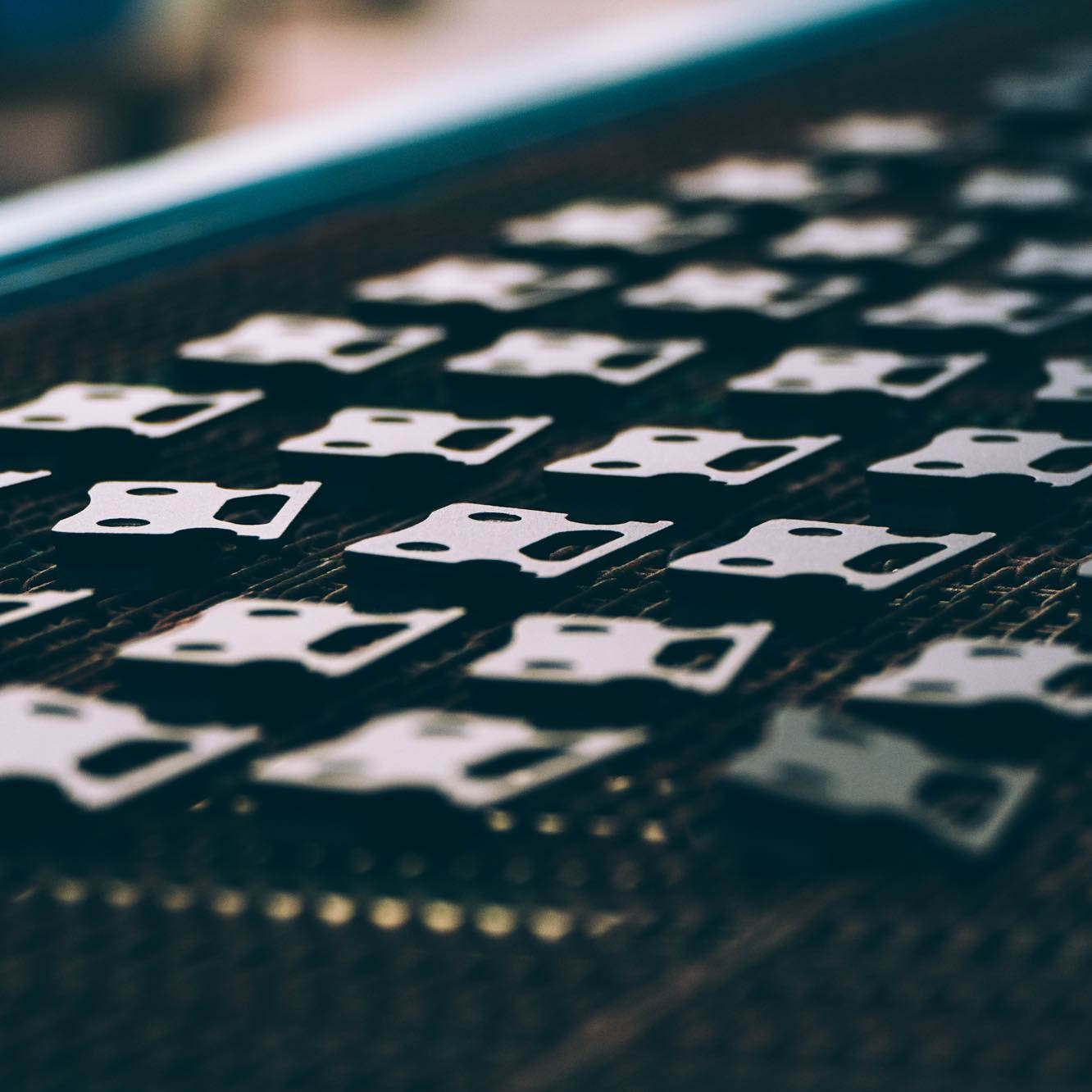

In its 50 years of existence, Sinter has been proud to supply brake pads to the winners of over 50 world go-kart champions. For us, and the industry as a whole, this is a noteworthy achievement that the young generations today would say is “next level”. And that’s exactly what we do, namely provide “next level” materials for the best go-kart teams and rental businesses in the world, as well as OEM manufacturers.

Our unique approach to each individual racer and his needs, along with the possibility to develop unique braking materials for specific target groups, gives us the chance to improve rapidly – and become better with every season, and even between seasons if needed!

WE PRODUCE MORE THAN 500 TYPES OF BRAKE PADS, DEVELOPED FROM SEVERAL OF OUR OWN FRICTION COMPOUNDS

CUSTOM

Sinter’s in-house R&D and production team can develop custom friction materials tailored to your needs.

With our deep expertise, we support customers in testing, refining, and selecting the optimal specification.

All our brake pads are available in the following 3 materials:

S-205 RENTAL

A low-wear material designed for durability and a stable friction coefficient.

• LONG-LASTING PERFORMANCE

• ORGANIC FORMULATION WITH LOW COPPER CONTENT

• FAST BEDDING-IN

• IDEAL FOR RENTAL APPLICATIONS

S-222 RACE

Developed for maximum braking loads in go-kart racing. Performs best with grey cast-iron brake discs.

• EXCEPTIONAL PERFORMANCE

• STRONG INITIAL BITE

• SEMI-METALLIC FORMULATION

• DESIGNED FOR RACING APPLICATION

S-230 ELITE

Our racing compound for the most demanding competitors. Excellent

modulation ensures complete control and confidence.

• OVERALL CHAMPION

• PURE RACING COMPOUND

• NO COMPROMISES

• SUPERIOR MODULATION

BEDDING-IN PROCEDURE

To ensure optimal braking performance and the best racing experience, every new set of brake pads must undergo a proper bedding-in process once installed in the braking system.

During this crucial phase, the brake pad surface adapts to the brake disc, while a transfer layer forms on the disc surface. This layer significantly improves friction stability and wear characteristics of the brake system.

Sinter recommends the following bedding-in procedure:

- 1 Ensure that both the brake disc and brake pads are correctly installed.

- 2 Make sure all braking surfaces are clean and dry.

- 3 Begin with slow driving and apply light braking for a few seconds to reduce speed without coming to a full stop. Repeat 20 times

- 4 Allow brakes to cool down.

- 5 Increase speed gradually over the next 5–10 laps. Apply moderate braking only, avoiding any hard stops.

- 6 Allow the brakes to cool after each lap.

- 7 Finish with several high-speed, hard-braking laps (2–3 laps).

- 8 Let the brakes cool down completely.

- 9 You’re now ready to race — and so are your brakes.

DISCS

EXTREME PERFORMANCE BRAKE ROTORS

Braking rotors are among the newest products in the Sinter product line, and a lot of customisation is possible. Our R&D is focused heavily on new composite materials.

HIGH CARBON GREY CAST IRON

We have partnered with the local university and metallurgical laboratories to develop the new high carbon grey cast iron rotor. These high-performance cast-iron brake rotors work perfectly with Sinter brake pads – available both as OEM and aftermarket.

CLUTCHES

A CLUTCH FOR EVERY STANDARD

Sinter produces both centrifugal and lamellar clutches, available as replacement parts or as performance-upgrade units for your go-kart. Our continuous development of advanced friction materials ensures that our clutch range meets the needs of even the most demanding racers.

CUSTOM SOLUTIONS

Sinter’s in-house R&D and production team can develop fully custom clutch components upon request.

With our extensive expertise, we support customers in testing, prototyping, and selecting the optimal clutch geometry and material composition.

LAMELLAR CLUTCHES – ARAMID COMPOSITE + MMC

By combining our advanced friction material with lightweight MMC middle plates reinforced with aramid fibers, we significantly reduced clutch weight, achieving up to 60% weight reduction compared to a standard steel middle plate.

WEIGHT OPTIMIZATION

We are committed to reducing clutch plate weight as much as possible.

We achieve this through:

- lightweight alloys and composite base plates

- friction materials with no metallic components

- advanced aramid + MMC combinations for extremely lightweight clutch assemblies

Key Advantages:

/ DYNAMIC PERFORMANCE

/ EXCELLENT TEMPERATURE RESISTANCE

/ LONG SERVICE LIFE

CENTRIFUGAL CLUTCHES

We offer centrifugal clutches for all engine types – Iame, Tm, Rotax and others.

There are two materials available:

Designed for non-slipping clutch applications, featuring:

- consistent performance

- strong temperature resistance

- long service life

A special formulation for extreme racing conditions, ideal for:

- aggressive race starts

- high thermal loads

- maximum durability in all conditions