WHY ORGANIC?

Sinter only make organic brake pads. Both organic and metallic pads are manufactured using a bonding process. Occasionally there is confusion around our name but we always like to point out we only make organic pads.

Organic pads are comprised of different types of fibres and materials. Each compound is a fine balance between lubricants and abrasives. It’s a little bit like baking a cake - small changes to ingredients or combinations can result in significantly different braking characteristics.

We use fibres such as kevlar, ceramics, clay minerals and carbon combined with resins.

Our friction materials R&D lab go to great lengths to develop pads that deliver particular characteristics to suit individual riding styles and perform exceptionally.

One of the greatest benefits of organic pads is that they transfer less heat into the calliper via the rotor. They don’t conduct heat as readily as metallic pads so the braking energy is retained in the pad and rotor - the result is a more stable braking system with greater modulation and predictability.

Organic benefits

Organic pads have greater feel and offer more feedback at the brake lever

They offer superior modulation and control for a better ride experience

They are quiet! Overall, organic pads make very little noise as long as they are properly bedded in and the system set up correctly

Less rotor wear and vibration. Sintered pads wear rotors faster and can create vibrations in the brake system

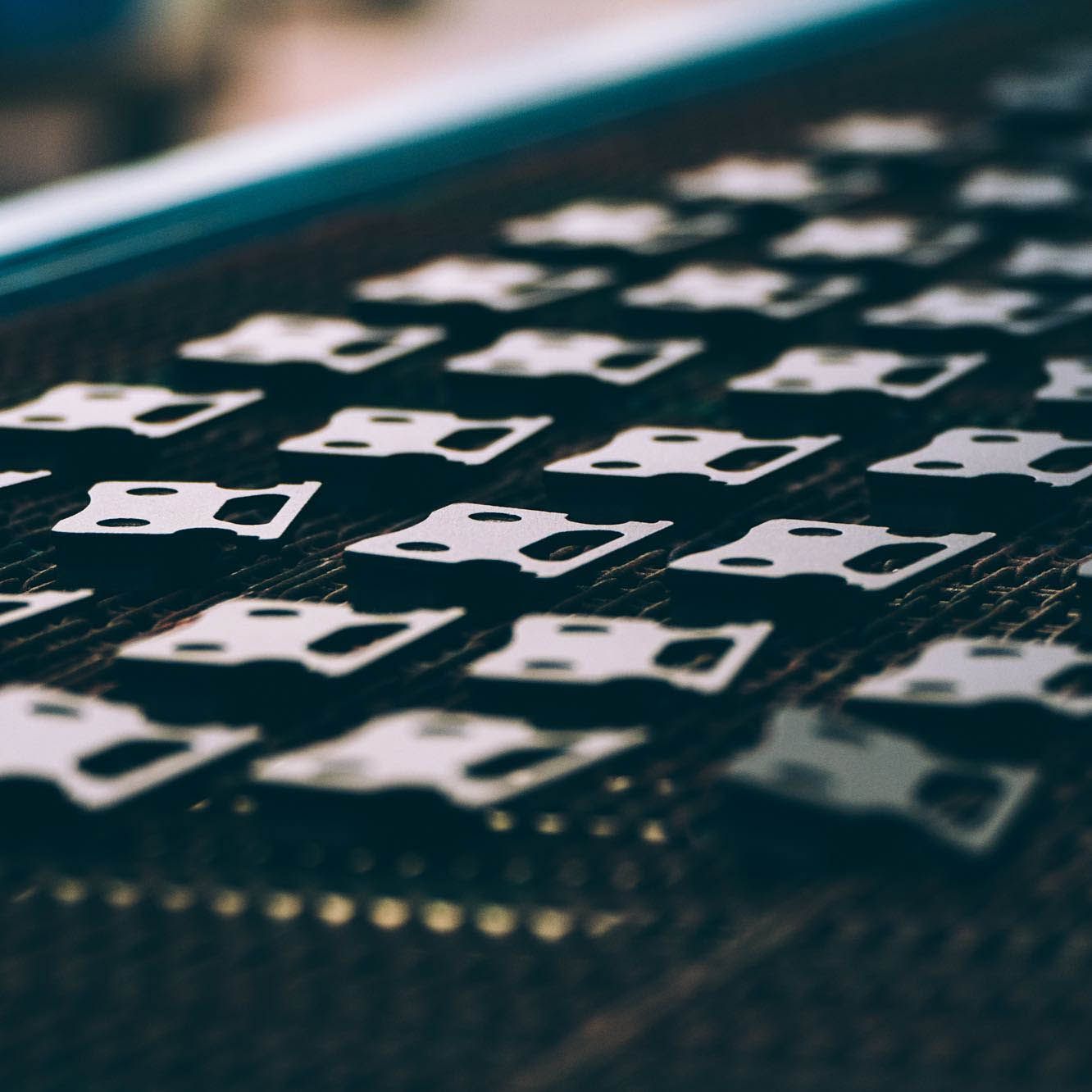

FRICTION MATERIAL

Friction material is a fine balance of lubricants and abrasives. At Sinter each pad compound is a careful blend of:

- Fibre re-inforced polymer composites

- Engineered mineral fibres

- Clay minerals

- Aramid fibres

- Carbon fibres

- Graphite

- Synthetic Lubricants

By varying the balance between these raw materials we can create pads with varying properties to suit different conditions, riding styles and brake systems

UPGRADE YOUR PADS

Sinter organic pads are a step-up in performance from OEM supplied brake pads. Testing on our in house BTM-11 dynamometer shows up to 44% higher coefficient of friction over competitors pads, an upgrade which can transform your braking system. Less force at the brake lever means reduced rider fatigue and more flow.

DEVELOPMENT

With over 50 years in developing friction products Sinter has grown to be one of the most trusted names in the industry.

Working with some of the more significant brands in the high performance sectors of motorcycling, karting and bicycles with disc brakes

To constantly develop and improve our products we utilise our own R&D facility and work with race teams and athletes in the MTB World Series and Pro Peloton.